How 2025 Tariffs Are Reshaping U.S. Industries and Companies

In early 2025, President Donald Trump imposed significant tariffs on imports from Canada, Mexico, and China, aiming to bolster domestic manufacturing and protect American jobs. These measures have had profound implications across various sectors of the U.S. economy, notably affecting automakers, consumer electronics, retail, and semiconductor companies.

1. Automakers & Auto Parts Suppliers

Tariffs Imposed:

- 25% tariff on steel and aluminum imports from Canada.

Impact:

-

Increased Production Costs: The automotive industry heavily relies on steel and aluminum, making vehicles more expensive to produce.

-

Price Hikes for Consumers: Manufacturers may pass on the increased costs to consumers, leading to higher vehicle prices.

-

Supply Chain Disruptions: Tariffs on imports from Mexico and Canada disrupt established supply chains, causing operational inefficiencies.

Companies Affected:

-

General Motors (GM) & Ford (F): Both companies source significant amounts of raw materials and parts from Canada and Mexico, making them vulnerable to increased costs.

-

Tesla (TSLA): Imports lithium-ion batteries and AI chips, facing higher costs due to tariffs on Chinese goods.

-

BorgWarner (BWA) & Aptiv (APTV): Auto parts manufacturers dependent on global semiconductor supply chains, now facing increased costs.

Related: Tariffs Threaten to Decimate U.S. Businesses: A Crisis Looms

Related: Canada, Mexico, and China Strike Back: Retaliatory Tariffs

2. Consumer Electronics & Tech Hardware

Tariffs Imposed:

- 20% tariff on Chinese imports.

Impact:

-

Rising Manufacturing Costs: Many electronic components are produced in China, leading to increased costs for consumer devices like smartphones and laptops.

-

Supply Chain Bottlenecks: Trade tensions may cause delays and shortages in essential components.

Companies Affected:

-

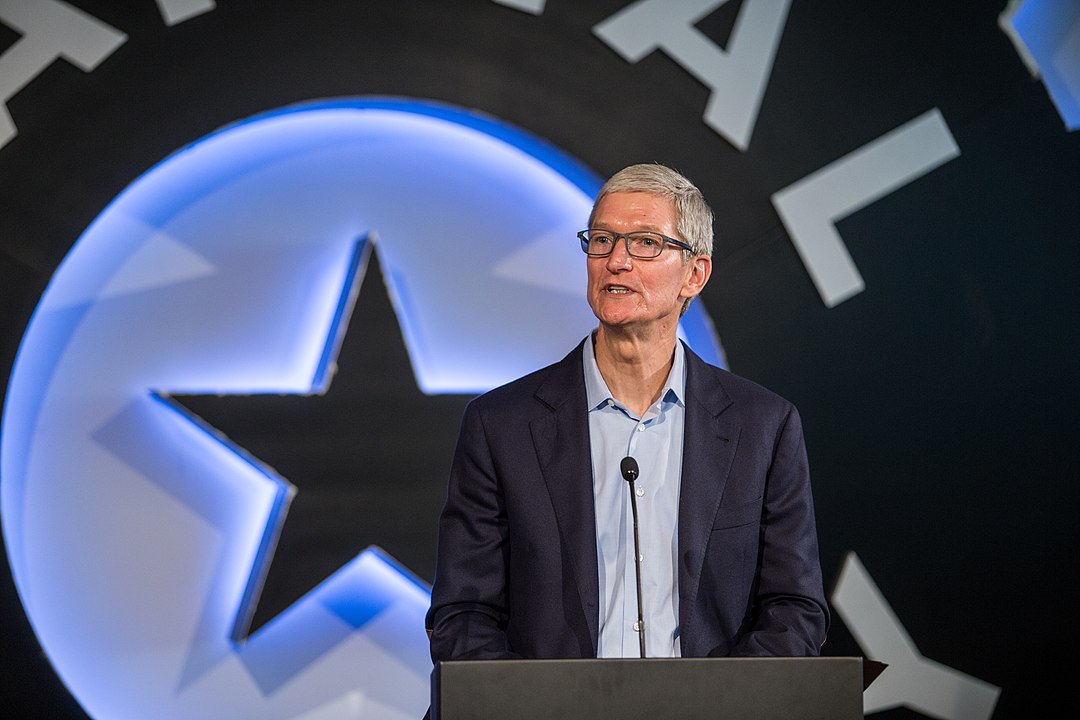

Apple (AAPL): Relies on Chinese manufacturing and Taiwanese semiconductor suppliers, facing increased production costs.

-

Dell (DELL) & HP (HPQ): Depend on global laptop and server production hubs, now subject to higher tariffs.

-

Cisco (CSCO): Experiences increased costs on networking equipment and enterprise hardware solutions.

3. Retail & Apparel Companies with High Import Dependence

Tariffs Imposed:

- 20% tariff on Chinese imports.

Impact:

-

Increased Product Costs: Over 40% of U.S. apparel and footwear is imported from Asia, leading to higher prices.

-

Reduced Profit Margins: Retailers may absorb some costs, impacting profitability.

-

Potential Decline in Consumer Demand: Higher prices could deter consumers, affecting sales volumes.

Companies Affected:

-

Nike (NKE): Major supplier factories are based in China and Vietnam, leading to increased costs.

-

Adidas (ADDYY): Global sportswear brand with significant Asian manufacturing exposure, facing similar challenges.

-

Target (TGT) & Walmart (WMT): Large-scale importers of consumer goods from tariff-affected countries, potentially passing costs to consumers.

4. Semiconductor Companies with Global Supply Chain Exposure

Tariffs Imposed:

- 20% tariff on Chinese imports.

Impact:

-

Increased Production Costs: U.S. chipmakers depend on Taiwanese foundries for production, leading to higher costs.

-

Supply Chain Disruptions: Tariffs on semiconductors from Taiwan and South Korea could increase costs for major firms.

Companies Affected:

-

Nvidia (NVDA): Relies on TSMC (Taiwan Semiconductor Manufacturing Co.) for advanced chip fabrication, facing increased costs.

-

AMD (AMD): Outsources semiconductor production to foreign chip foundries, now subject to higher tariffs.

-

Intel (INTC): Despite U.S. fab expansion, Intel still sources critical components globally, leading to increased costs.

2025 Tariff Updates

As of March 2025, the White House announced that the tariffs are prompting numerous major companies to enhance their U.S. manufacturing efforts. Firms from various sectors, including automotive, technology, and apparel industries, are planning to expand production within the United States to circumvent the tariffs. Companies like Honda, Hyundai Motor, Stellantis, Volkswagen, and Volvo Cars are exploring new factories or increased production at existing sites in the U.S.

Additionally, U.S. car buyers are rushing to dealerships to purchase vehicles before potential price hikes due to the tariffs. This uncertainty has led to a significant spike in car searches on various platforms, with dealers currently having sufficient inventory